The Client Story

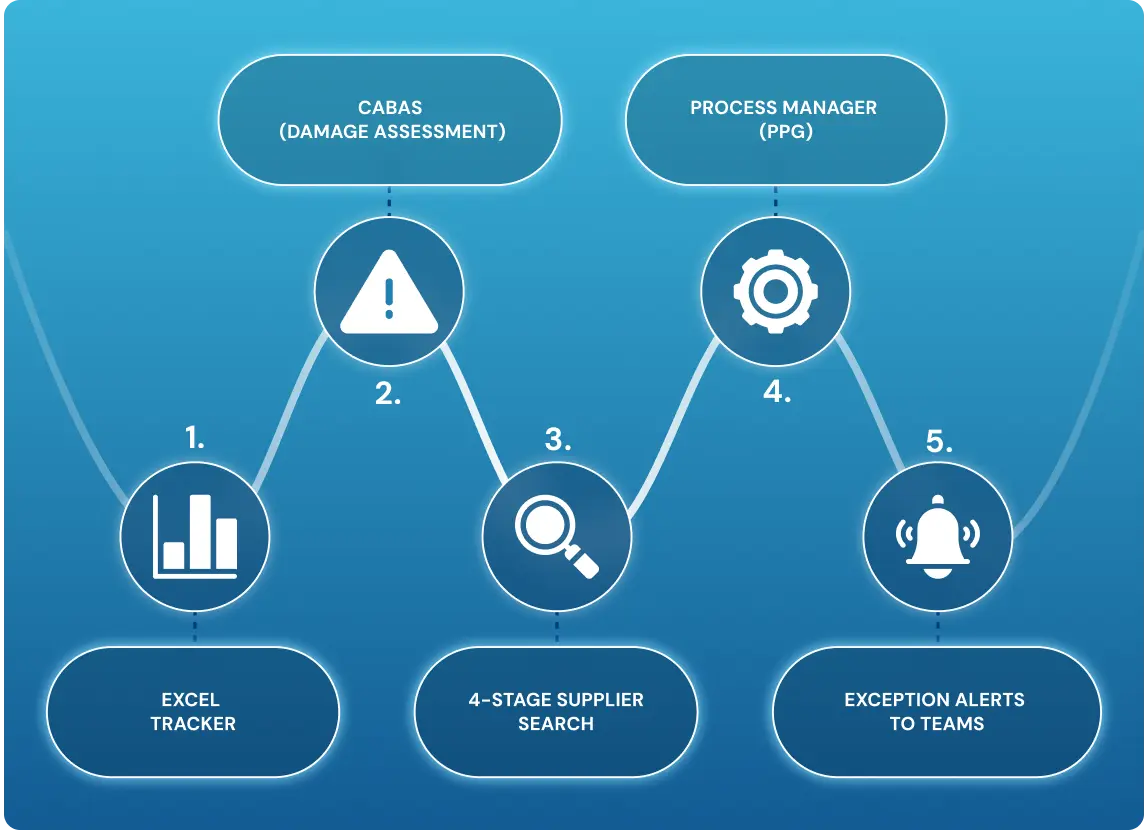

A leading Nordic automotive repair group faced an operational ceiling. Service quality remained strong, yet sourcing replacement parts created constant friction. The procurement workflow consumed hours per claim and diverted staff from higher-value repair work. Each case required administrators to juggle the initial parts requirement system (CABAS), a four-stage supplier search, the Process Manager (PPG) parts ordering system, and a central Excel tracker.

| Industry: | Automotive |

|---|---|

| Cooperation: | 2025 |

| Location: | Nordic Region |

“Growth was constrained by administrative bandwidth. Each new claim strained capacity further. Scaling people alone could not solve the challenge.” — Chief Operating Officer, Nordic Automotive Company

“The impact was immediate. Automation removed the ceiling on growth and gave us space to focus on customers again.” — Chief Executive Officer, Nordic Automotive Company

Fragmented, High-Friction Workflow

The organization needed to decouple growth from linear increases in headcount. The workflow had to be automated end-to-end, from Excel triggers through the initial claim/part specification system to staged supplier outreach, and finally to parts ordering.

The automation required four key capabilities:

- Initiate automation based on status changes within a central Excel tracker.

- Control multiple desktop applications.

- Execute a four-stage supplier search with failover logic.

- Escalate exceptions directly to staff.

This was not a case of scripting clicks. It required orchestration that combined precision, resilience, and auditability.

RPA Orchestration Built for Scale

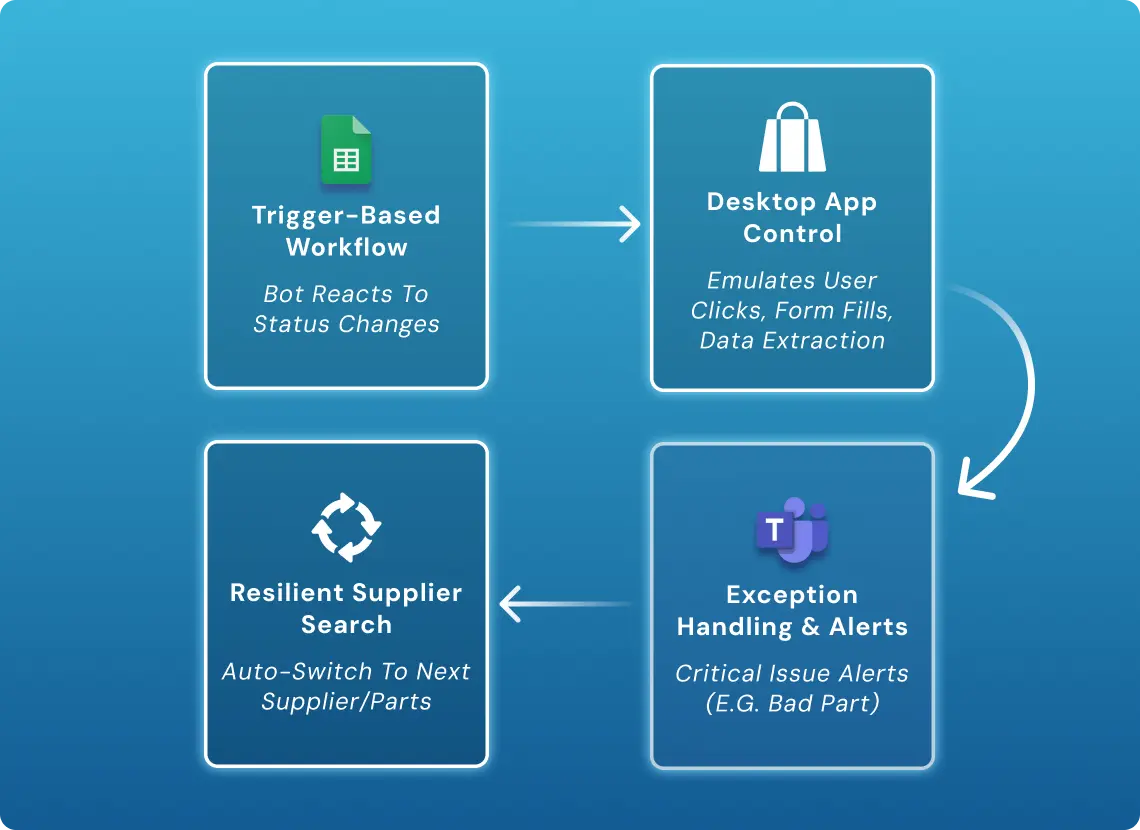

GroupBWT assigned two Python engineers with expertise in workflow automation. Over the course of two months, they delivered a Robotic Process Automation (RPA) bot designed to operate as a digital administrator.

- Trigger-Based Workflow: The bot used status changes in the central Excel file as a trigger, ensuring every automated action was initiated at the right moment.

- Desktop App Control via UI Automation: It directly manipulated the CABAS and Process Manager (PPG) desktop applications by emulating user actions—such as clicks, form fills, and data extraction—to seamlessly manage the workflow without requiring APIs.

- Resilient Supplier Search: The bot executed a complex four-stage supplier search with built-in failover logic, automatically moving to the next supplier or switching to ordering new parts if a response was not received.

- Intelligent Exception Handling: Every action was logged for full auditability. Critical exceptions, such as a supplier offering a low-quality part, triggered instant, context-rich alerts in Microsoft Teams for human intervention.

The challenge was context, not clicks. The bot executed rules flawlessly and escalated only when necessary.

Scalable Efficiency Unlocked

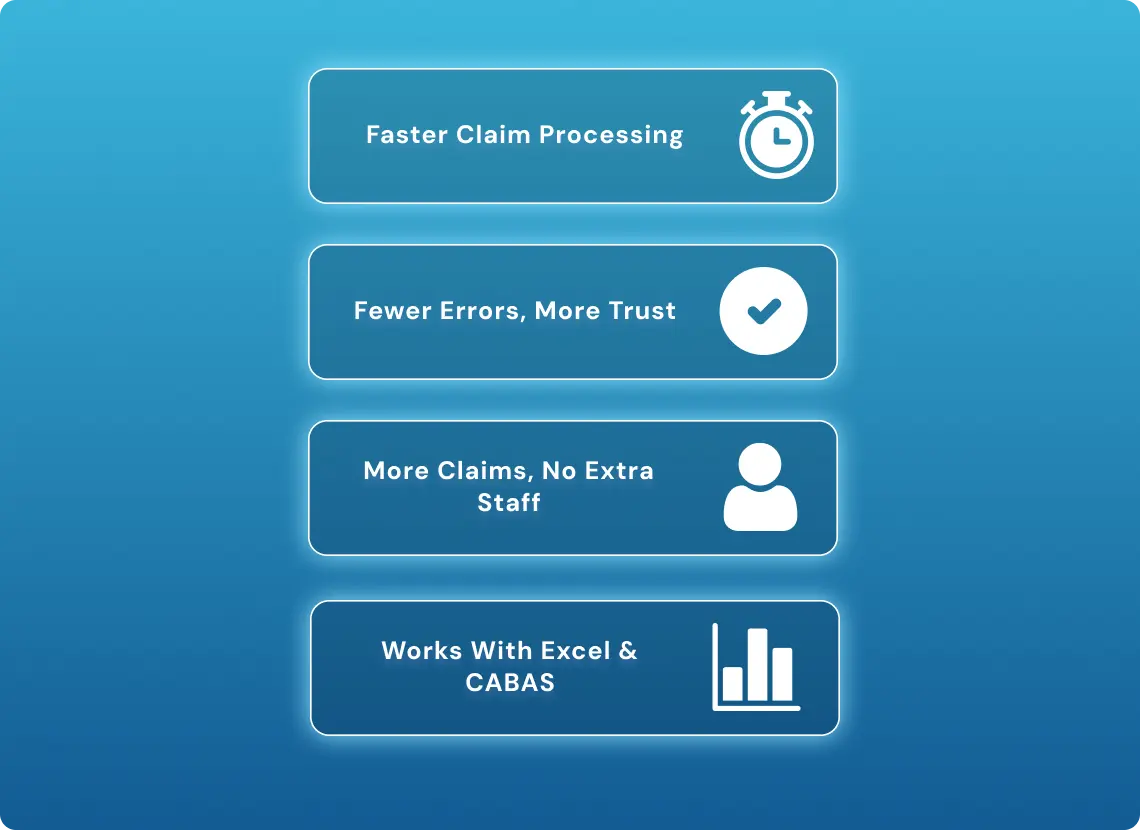

The automation delivered a measurable, immediate impact:

- 80% less manual time per claim.

- 45% greater claim capacity without new hires.

- 99%+ fewer errors, eliminating mismatches and missed follow-ups.

The repair group shifted from bottlenecked processes to scalable throughput. Faster turnaround strengthened insurer partnerships. Reduced error rates protected the margin. Teams could finally focus on complex repair and customer service instead of repetitive entry work.

Executive Takeaways

- Administrative bottlenecks cap growth in service-heavy industries.

- RPA reduces claim cycle time by up to 80%.

- Error elimination improves insurer confidence and lowers rework costs.

- Automation increases capacity without inflating payroll.

- Audit-ready orchestration preserves continuity across legacy systems.

Automate Workflows, Scale Capacity, Protect Margin

Book a 30-minute discovery session with GroupBWT’s automation team to evaluate how custom RPA can accelerate claims and procurement workflows.

You have an idea?

We handle all the rest.

How can we help you?