Forecasting cycles shifted from quarterly estimates to daily recalibration. Executives who embed AI into forecasting gain faster reaction, sharper accuracy, and measurable ROI across industries.

- McKinsey Global Institute estimates $60-110 billion annual impact from generative AI adoption in pharmaceuticals. Demand forecasting contributes to this value through accelerated drug discovery and improved planning efficiency.

- AI-driven forecasting in FMCG reduces errors by 20-50%. McKinsey research shows up to 65% fewer lost sales, directly lowering inventory costs at enterprise scale.

- Global generative AI spending reaches $644 billion in 2025.

- Gartner forecasts 76.4% year-over-year growth, driven primarily by hardware investments and enterprise adoption.

- Scaling follows enterprise maturity stages. MIT research identifies a four-stage progression from experimentation to full AI integration, with higher maturity correlating to above-average financial performance.

This article synthesizes 2025 research, case studies, and maturity models into a single framework leaders can act on—covering both operational outcomes and capital stakes.

The Shift from Traditional to AI Driven Demand Forecasting

Boards once relied on statistical models trained on historic sales. Those models assumed stable trends. They delivered outputs only as good as the lagging data inside them. By the time numbers reached the executive floor, the market had already moved on.

As the demand sensing overview, older models cannot process granular, high-frequency inputs. They fail when supply chains need daily recalibration.

How Does AI Help in Demand Forecasting?

By replacing backward-looking averages with forward-looking signals. Algorithms detect short-term demand shifts by reading sales velocity, promotions, and regional patterns. Executives gain warnings before stock runs out or excess builds up.

AI in demand forecasting is not about more complex math. It is about speed and relevance. Models that ingest live data streams remove the lag that leaves teams overstocked in one region and understocked in another. The outcome is a faster response with lower waste.

Executives who still rely on traditional forecasting methods are effectively running operations with a permanent delay. AI turns forecasting into a present-tense activity.

Core Technologies Behind AI Based Demand Forecasting

Executives hear “AI” often. The substance lies in the systems that make AI forecasting of demand reliable at scale.

Machine Learning & Neural Networks

Machine learning models uncover relationships across thousands of inputs—price, channel, weather, and promotion data—without hand-coded rules. Neural networks extend this by spotting non-linear patterns that conventional models miss. As the IJSAT 2025 paper on retail forecasting shows, these approaches generate sharper short-term forecasts than regression models have ever delivered. That difference removes costly lags from procurement and production decisions.

AI and Machine Learning in Demand Forecasting

AI and ML in demand forecasting move supply chains from fixed timetables to adaptive flows. This matters less for the novelty of technology and more for balance sheet outcomes.

Lower error rates translate directly into fewer lost sales and fewer markdowns. For executives, the driver is not algorithmic complexity. It is capital efficiency.

AI for demand forecasting enables supply chains to mirror demand as it forms, not after it is tallied. That distinction defines competitive advantage in 2025.

How AI Powered Demand Forecasting Is Transforming Industries

Leadership teams across sectors face the same structural problem: unpredictable demand cycles. How AI is transforming demand forecasting shows up when industries with different rhythms adopt the same logic.

Consumer Goods & Retail

Companies use demand sensing to “conquer supply chain chaos.” Algorithms detect shifts in consumer buying behavior within days.

Supply Chains of the Future

Supply chains depend on agility, not linear planning, positioning AI as the driver of “supply chain maturity.” Real-time forecasting systems enable planners to simulate disruptions and reroute inventory dynamically.

Executives treat these systems as risk absorbers. By testing scenarios in advance, organizations avoid exposure to sudden shifts in demand or logistics bottlenecks.

Multi-Industry Examples

AI/ML demand forecasting scales across industries because the principle stays constant: integrate live signals, correct forecasts daily, and reduce errors. GroupBWT cases range from automotive to healthcare. In every case, machine learning improved forecast reliability and inventory efficiency. Transformation happens industry by industry, but the mechanics repeat.

- Finance anticipates liquidity and investment needs before risks materialize.

- HR plans workforce capacity with models that highlight attrition patterns.

- Manufacturing reduces downtime through predictive maintenance.

- Marketing and Sales adapt campaigns in real time based on conversion likelihood.

Predictive modelling no longer sits in the supply chain. They operate as a shared decision layer across the business.

Customer retention also depends on predictive intelligence. By integrating these models into CRM systems, enterprises turn forecasting insights into direct loyalty gains.

How to Do Demand Forecasting Using AI

Effective demand forecasting requires AI tailored to specific business use cases. The challenge is execution. AI based demand forecasting requires a staged path from pilot to full adoption. Companies that skip structure face failed projects and eroded trust.

Steps and Best Practices

Successful teams follow consistent steps. GroupBWT lays out a process:

- Align forecasting goals with measurable outcomes such as error reduction or inventory savings.

- Cleanse and structure historical and transactional data.

- Integrate external signals like promotions, weather, and competitor actions.

- Deploy AI in controlled pilots and expand once accuracy improves.

AI in demand forecasting succeeds when leaders treat it as a system, not a side project. Each step builds confidence with measurable gains.

Implementation fails when executives assume models will self-correct without governance. Inconsistent data, lack of integration, and overreliance on one signal erode forecast quality.

Forecasting systems degrade when they lack ongoing oversight. Enterprises avoid this by adopting lifecycle management practices that monitor, retrain, and adapt models over time.

Executives enforce discipline to keep AI demand forecasting reliable. Structured oversight prevents accuracy loss, controls ownership cost, and reduces disruption risk. MLOps converts forecasting into a continuous service, not a project with an expiry date.

Future Outlook: AI Forecasting and Industry 4.0

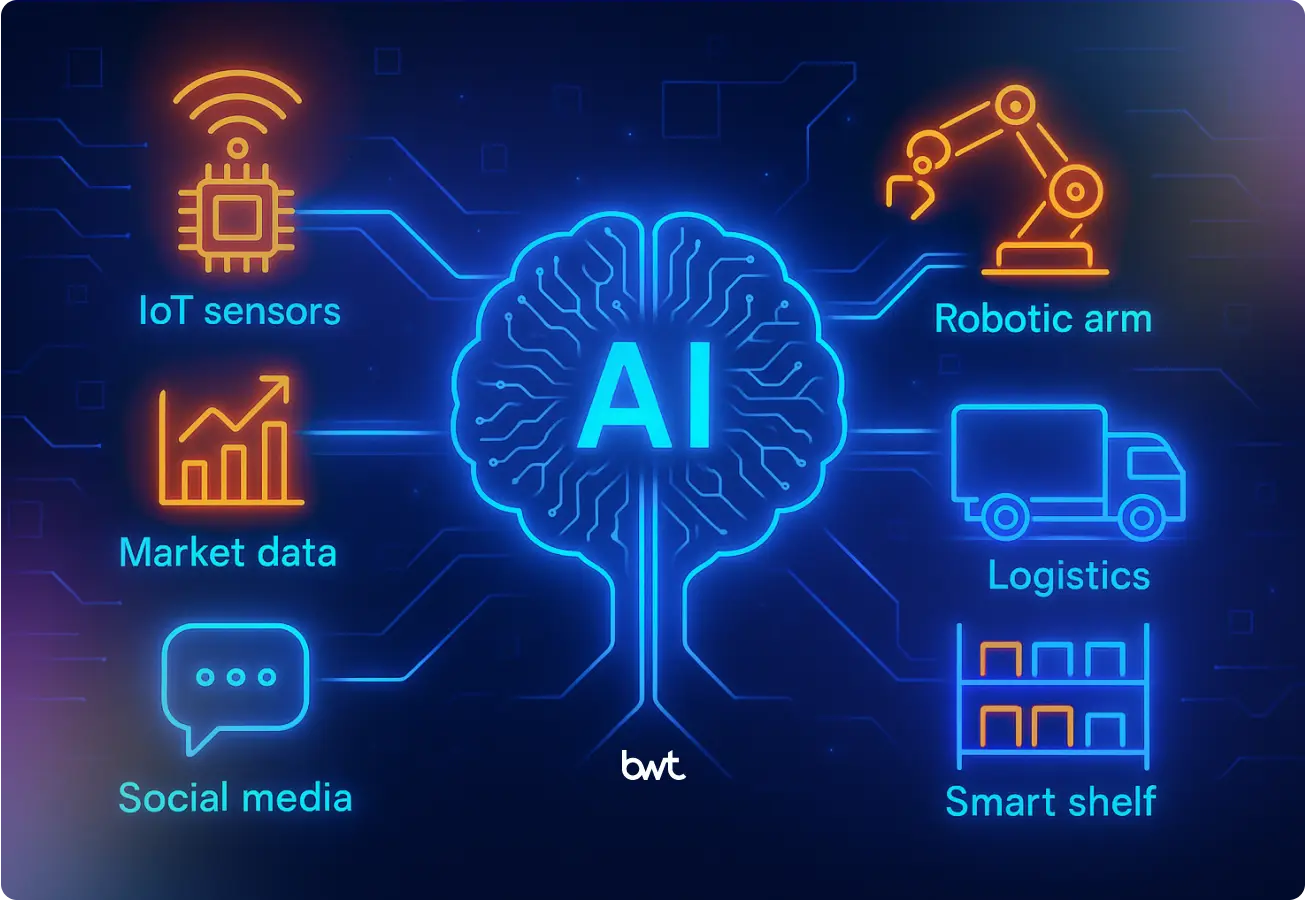

AI in forecasting no longer evolves in isolation. It now operates inside the Industry 4.0 shift, where factories, supply chains, and markets connect in real time. This phase is not incremental efficiency. It is synchronized ecosystems where forecasts drive production, logistics, and sales as a single loop. AI powered demand forecasting acts as the control system that holds this loop in alignment.

Industry 4.0 and Next-Generation AI

Industry 4.0 introduces connected machines, sensor-driven data, and autonomous decisions. Forecasting tools in this environment must process live signals across manufacturing, distribution, and retail simultaneously.

AI for demand forecasting does not simply adjust inventory—it coordinates capacity planning, supplier schedules, and workforce deployment within a single, adaptive framework.

L’Oréal’s work on Industry 4.0 illustrates this trajectory. Their demand sensing platforms now integrate directly into smart factories, where production lines recalibrate based on daily shifts in consumer demand. Instead of planning at a distance, forecasting connects straight to operational levers. That linkage reduces waste, accelerates product availability, and strengthens the speed of market response.

In an Industry 4.0 environment, forecasting cannot remain an afterthought. It becomes the nervous system of digital operations, powered by AI to predict, balance, and act across every stage of the value chain.

Data Foundations for AI in Forecasting

AI in forecasting delivers results only if the data feeding it is structured, consistent, and complete. AI demand forecasting requires pipelines that unify multiple sources into one system that executives can trust.

Core Data Sources

- Internal signals: sales transactions, POS systems, ERP data, CRM records.

- External signals: competitor prices, promotional calendars, economic indicators, and weather.

- Unstructured data: product reviews, social sentiment, IoT devices in logistics.

Integration and Governance

Forecast quality depends on governance. Companies that fail to cleanse and normalize inputs see error rates climb. Governance frameworks must set rules for:

- Data freshness (daily, hourly updates)

- Access controls and compliance

- Consistent metrics across business units

Organizational Adoption and Change Management

AI for demand forecasting reshapes workflows. Leaders cannot assume models will replace planners. Instead, they redefine how teams interpret and act on AI insights.

Stakeholder Alignment

- Finance teams need visibility into capital planning.

- Supply chain teams rely on safety stock alignment.

- Sales and marketing teams track promotional impacts.

Without shared ownership, forecasts remain siloed.

Training and Trust

Executives must train staff to interpret AI outputs with confidence. When planners understand why an AI model adjusted forecasts, adoption accelerates. GroupBWT’s best companies to work for data science highlight the importance of transparency in scaling AI/ML systems across enterprises

Risks in AI Demand Forecasting

Executives cannot treat AI demand forecasting as a guaranteed win. Each measurable ROI comes with structural risks that require active governance and clear accountability.

Model Bias and Transparency

AI in forecasting reflects the data it consumes. Historical distortions, skewed consumer signals, or incomplete feeds embed flaws directly into outputs. Executives demand transparency to prevent misallocation of capital and distorted forecasts. If governance fails, biased AI based demand forecasting models accelerate errors across procurement and pricing cycles.

Talent and Organizational Gaps

AI for demand forecasting fails without skilled operators. Engineers, MLOps teams, and supply chain analysts keep models accurate and explainable. Shortages stall adoption and create dependence on opaque outputs. Boards must invest in cross-functional training, since AI and machine learning in demand forecasting only delivers resilience when staff can interpret and adjust signals in real time.

Regulatory and Compliance Pressures

AI powered demand forecasting relies on sensitive consumer, transaction, and IoT data. Global regulations on privacy, cross-border flows, and algorithmic accountability continue to tighten. PwC warns that compliance failures cut 3–5 points from margin through fines and disrupted contracts. Boards embed frameworks early to ensure demand forecasting using AI scales without exposing continuity risks.

Operational Overreliance

AI/ML demand forecasting improves accuracy, but reliance without oversight creates fragility. If teams delegate critical calls to algorithms alone, anomalies remain unchecked. Executives impose dual control: algorithms recommend, managers decide. That balance converts forecast accuracy into preserved margin instead of hidden exposure.

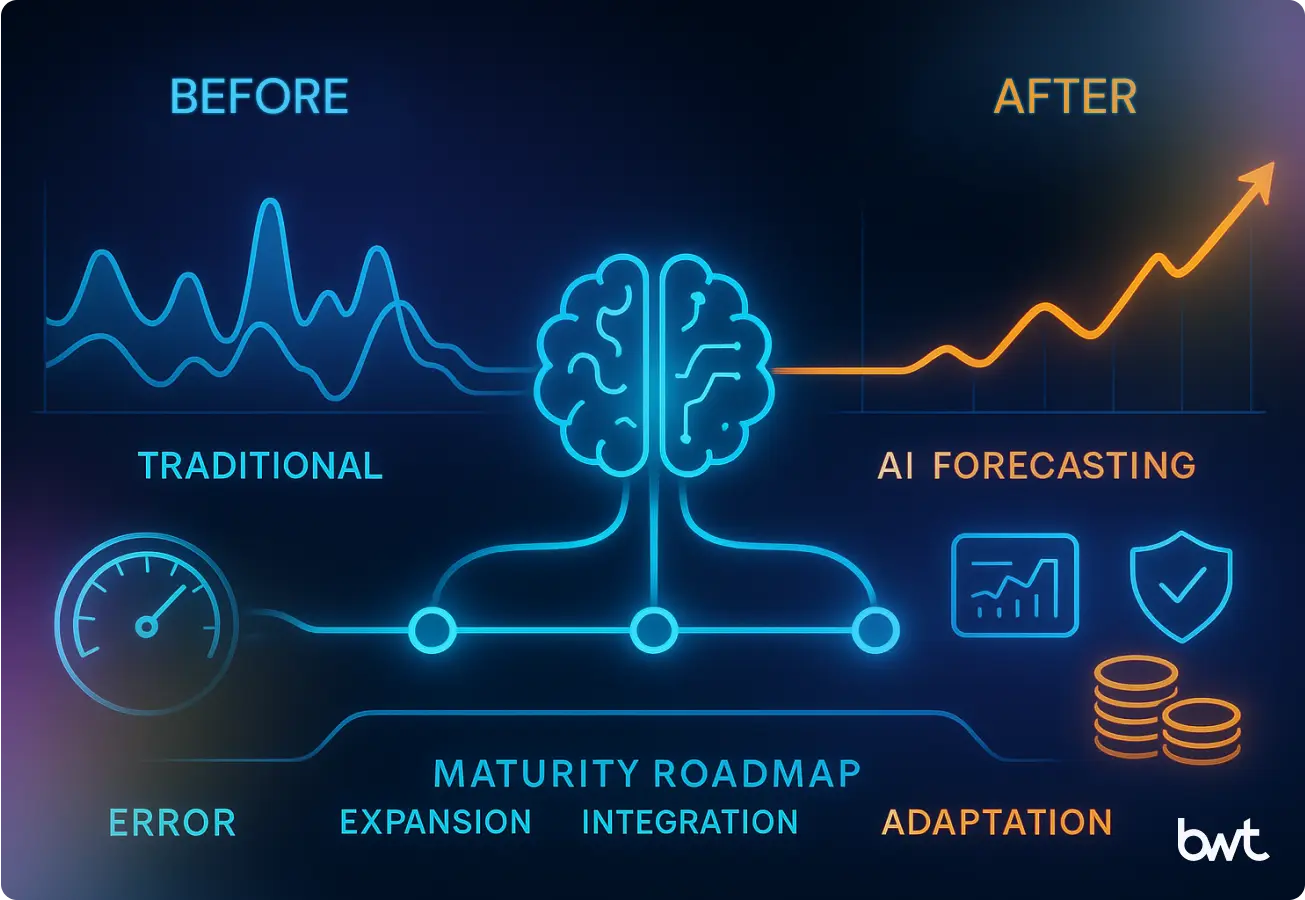

Scaling AI Driven Demand Forecasting Maturity

Adoption follows maturity stages. Companies progress from pilots to enterprise integration by building confidence step by step.

Maturity Roadmap

- Pilot phase: narrow scope, validate accuracy within 10–16% error.

- Expansion: integrate external signals, expand forecasts across new regions.

- Enterprise integration: embed AI demand forecasting into ERP and BI systems.

- Adaptive ecosystems: daily decisions in logistics and procurement run on AI in demand forecasting.

AI in demand forecasting brings sharper precision but amplifies risks without discipline. Governance reduces bias, training sustains adoption, compliance protects contracts, and oversight prevents overreliance. Enterprises that enforce these safeguards cut volatility by up to 30% and maintain continuity when cycles compress. The lesson is blunt: scaling AI based demand forecasting requires as much organizational rigor as technical sophistication.

As L’Oréal’s demand sensing research confirms, forecasting now requires systems that react in real time to fast-changing demand cycles. This is not about bigger datasets but about using AI to recognize shifts before they cascade into missed sales or tied-up capital.

AI Based Demand Forecasting in 2025: From Accuracy Gains to Strategic Transformation

Traditional forecasting methods, which rely on historical averages, report error rates of 25–40%. The International Journal on Science and Technology confirms that AI-driven forecasting systems reduce these errors to 10–16%.

Complementary evidence from the World Journal of Advanced Engineering Technology and Science, in the study 7 Ways AI Is Revolutionizing Supply Chain Forecasting and Optimization, shows that AI integration lowers Weighted Absolute Percentage Error (WAPE) by 40–75% and reduces forecast bias by 30–70%. These reductions directly improve inventory balance and reduce disruption risk.

The McKinsey Global Institute estimates that generative AI adoption in pharmaceuticals generates $60–110 billion in annual impact, particularly by improving demand forecasting for vaccines and seasonal drugs.

Implementation Path: Forecasting Maturity Timeline

The staged adoption model is widely documented. MIT Sloan Management Review outlines corporate progression from pilot to enterprise-level AI integration, while Veritis AI Maturity Model – A CEO’s Guide provides budget ranges:

- Pilot (0–3 months): $100K–500K budgets focused on accuracy validation.

- Expansion (6–12 months): Broader integration of external signals.

- Enterprise (18–24 months): Forecasting embedded into ERP and BI platforms.

- Adaptive (36+ months): AI becomes the operational core, with budgets exceeding $10M.

This maturity path enables executives to benchmark readiness and investment levels.

Supplementary Materials for Decision-Makers

Gartner forecasts that global spending on generative AI will reach $644 billion by 2025, driven by enterprise integration and consumer adoption.

An executive-ready presentation deck should cover:

- Forecasting performance benchmarks and ROI cases

- Maturity roadmap with investment phases

- Integration with Industry 4.0 ecosystems (digital twins, predictive maintenance, smart factories)

- Strategic next steps for leadership framing

Companies that embed AI in demand forecasting move from lagging reports to live decisions. The cost of delay is now measurable: every quarter without AI forecasting leaves executives managing expired numbers in live markets.

ROI Framework for Decision-Makers

Boards need clarity on how forecasting investments translates into performance gains. A structured view aligns inputs, outputs, and outcomes.

- Data integration improves forecast precision and reduces volatility.

- Predictive maintenance improves asset reliability and lowers unplanned costs.

- Customer modeling improves conversion rates and optimizes spend.

- Competitive and market data strengthen pricing decisions.

This framework links technical adoption directly to margin, risk, and speed of execution. As one of the best data analytics companies, GroupBWT provides the infrastructure to move from raw signals to decisions. Their outsource data mining service delivers structured external inputs that feed AI demand forecasting pipelines and sustain accuracy at enterprise scale.

Executive Decision Acceleration

How does AI help in demand forecasting? By converting inputs into decisions at executive speed. Leaders gain confidence when forecasts drive board-level choices.

AI-driven forecasts accelerate decisions in four areas:

1. Pricing: detect demand surges and adjust price bands dynamically.

2. Promotions: align campaign timing with predicted demand peaks.

3. Production: recalibrate capacity without overstocking.

4. Capital allocation: fund regions and SKUs with the strongest forecasted lift.

GroupBWT’s data analytics services provide the infrastructure to move from raw signals to decisions, showing how predictive models shorten planning cycles.

FAQ

-

What improvements does AI demand forecasting bring compared to traditional methods?

AI demand forecasting raises accuracy because models track live signals instead of relying on static historical averages. Forecasts recalibrate daily, reducing stockouts and cutting excess inventory. Service levels improve because replenishment follows current demand, not lagging estimates.

-

How does AI demand forecasting impact financial outcomes?

AI in demand forecasting reshapes financial outcomes by synchronizing production, inventory, and sales with real demand. Companies see fewer shortages, less tied-up capital, and margins that hold under volatile cycles. Boards treat it as a core investment because it links directly to profitability.

-

What steps are required for successful adoption at scale?

AI based demand forecasting succeeds when companies adopt a staged implementation. Teams start small to validate accuracy. Integration of external signals then expands coverage. Forecasting becomes embedded in enterprise systems that guide capital allocation and production planning. Skipping stages undermines accuracy. Structured expansion builds resilience and trust.

-

Which data sources matter most for accurate forecasting?

AI for demand forecasting relies on layered data. Internal signals—sales records, transactions, and customer activity—anchor the baseline. External inputs, such as weather and competitor activity, add variability. AI and machine learning in demand forecasting strengthen outcomes when unstructured data from sensors or reviews feeds the same governed pipeline. Alignment across these inputs drives measurable accuracy.

-

How does AI demand forecasting fit into Industry 4.0?

AI powered demand forecasting operates as the coordination layer in modern supply chains. Demand forecasting using AI connects digital systems in factories, logistics, and retail. Forecasts no longer sit in static reports. They trigger real-time adjustments in production and distribution, protecting continuity across the value chain.